- Home

- About Us

- Products

- Department

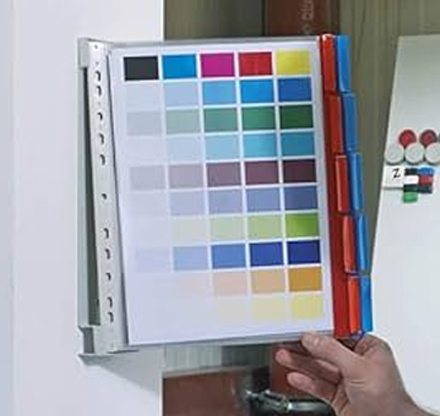

Raw Material

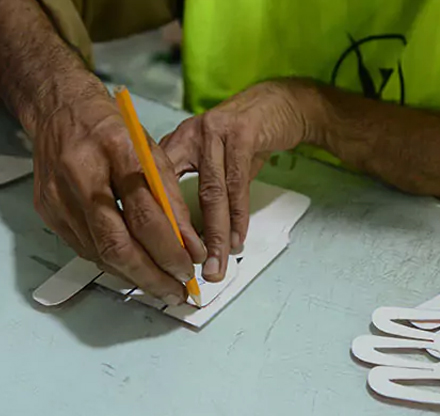

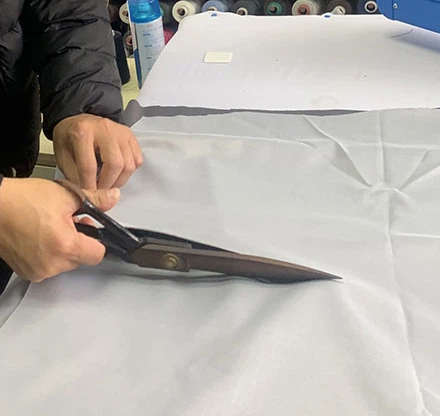

Pattern making &Cutting

Stitching

- Site Map

- Contact us

The development of a garment comprises of different process. Fit is the most important factor leading to the final acceptance or rejection of a garment. Fit must be designed into the original pattern through subtleties in the pattern that provide fullness unobtrusively at appropriate locations to accommodate body bulges in a flattering manner.

Grip Maker own his complete pattern scanning technology and the man power to arrange the new development as well.

Gerber Garment Technology (GGT) GGT has almost abolished the time consuming method of manual pattern making where a variety of sizes is needed. With GGT only one base size is required and from that as many patterns can be prepared as you want, in record time. This process is technically given the name of grading.

Seasoned fabric cake cutters are working in TDP (Grip Maker) to handle mass production. Three dedicated gigantic space facilities are operating for the cake cutting departments.

Manual cutting goes side by side with cake cutting as garments cutting comes in such quantities and complexities where cake cutting is avoided and cutting is done with conventional scissors.

All the sublimation print are cut in TDP manually by man power. We have the sublimation cutting capacity of 1800- Pcs per day.